Vii references vedat ari energetic and exergetic assessments of a cement rotary kiln system scientific research and essays vol.

Waste heat recovery system in cement plant pdf.

Customized cement kiln heat recovery solutions.

1428 1438 18 march 2011.

As a result the system design needs to be customized to maximize the benefit for the plant.

Rd d to advance waste heat recovery technologies.

The reduction in co 2 emission makes it environmental friendly.

Installation of the waste heat recovery plant has to be tackled as a system approach rather than considering cement plant and whrpp operations independently.

Waste heat is also available from the exhaust of diesel engines of dg set.

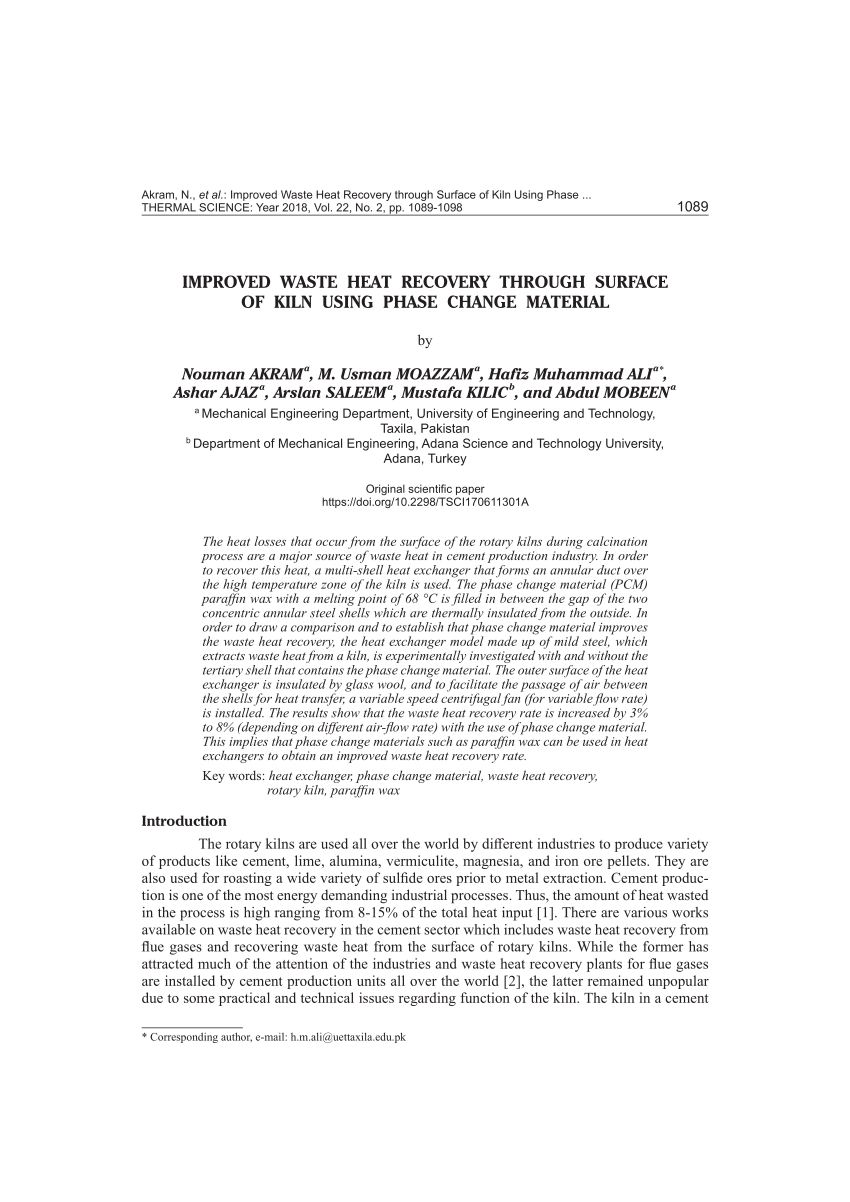

This study investigates the feasibility of installing the waste heat recovery system in tehran cement plant.

A waste heat recovery steam generation system was selected showing the energy saving potential of 2 62 mw from the waste heat streams with simple pay back of 30 months.

U we delivered a waste heat recovery power generation equipment for a coke oven which was constructed in the arcelor mittal tubarao.

Therefore after the efficiency of a cement plant has been driven to the economic optimum the remaining waste heat is converted into electricity.

Cement production is an energy intensive process.

This covered about 30 of factory power consumption contributing to a reduction of about 170 000 tons of co2 per year.

Every cement plant has unique characteristics whether it is the type of fuel fired in the kiln the number of preheater stages utility incentives cost of power these are different at every plant.

21mw waste heat recovery system for pukrang cement plant.

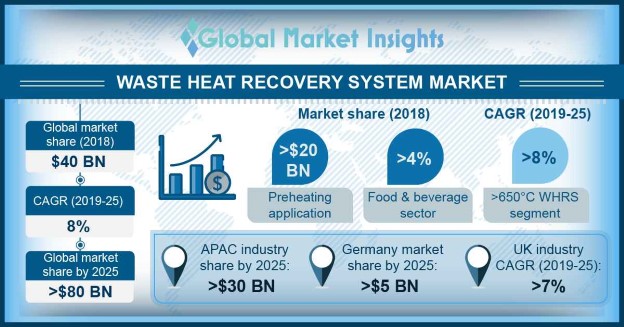

Waste heat recovery power plants contribute significantly to the electrical energy saving to the tune of 25.

A waste heat recovery system compris ing both steam and power turbines and combined with utilising scavenge air energy for exhaust boiler feed water heating.

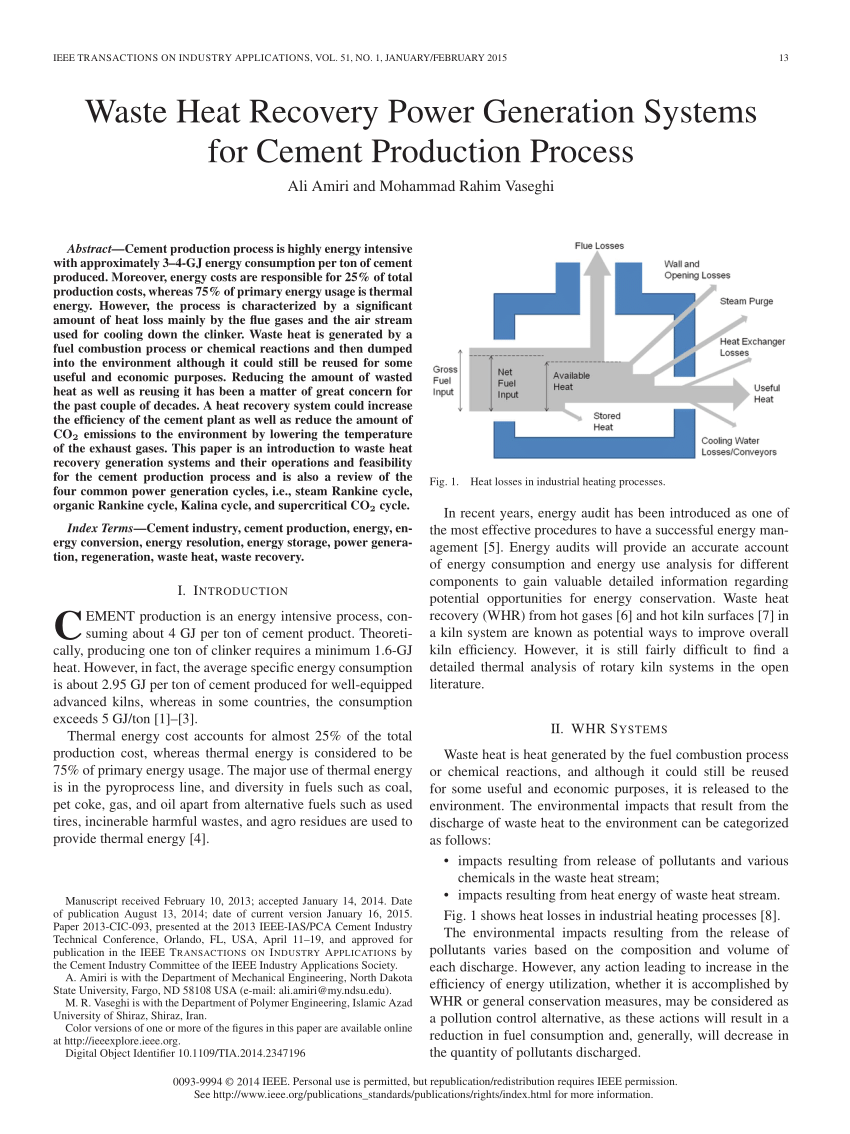

In a cement plant waste heat is available mainly from kiln exhaust gases and vent air from the clinker cooler.

The first step in planning to install a waste heat recovery system whrs is to work out the net available waste heat that can be used to generate power.

Waste heat recovery system.

Technology needs are identified in two broad areas.

1 extending the range of existing technologies to enhance their economic feasibility and recovery efficiency and 2 exploring new methods for waste heat recovery especially for unconventional waste heat sources.

Hakan uvez asia cement plc thailand filmed at cemtech asia 2015 21 24 june grand hyatt bangkok thailand login required a full subscription to international cement review magazine is required to view videos.