Wardjet is an ohio based designer and vertically integrated manufacturer of tailored waterjet cutting solutions that are used to cut materials ranging from tinfoil to titanium.

Water jet cut rate.

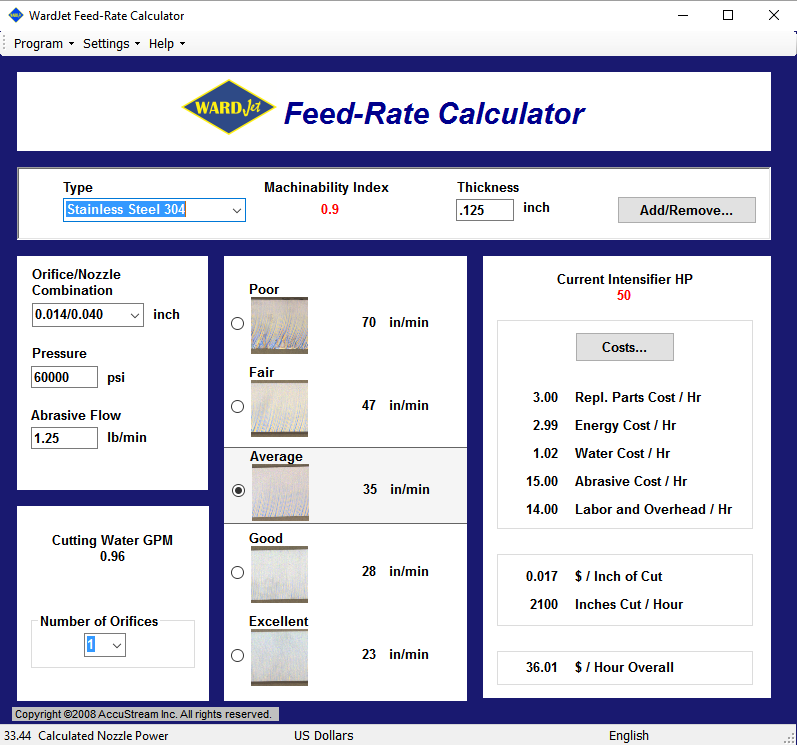

Get information about cutting feeds speeds for waterjet granite cutting titanium sheet water jet and many other metals.

Simply put the higher the pressure the faster the cut.

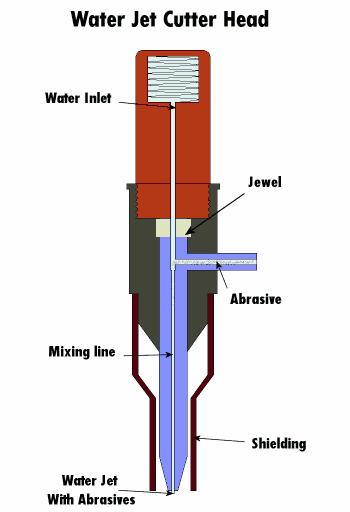

The less common microjet waterjet cutting heads have a smaller nozzle and stream width of 0 02 inches 0 5 mm.

Each of these costs represents the maximum water and abrasive flow rate for the largest orifice that can be driven by each pump at it s maximum pressure.

This is due to the waterjet cutting stream spreading out as it gets farther from the nozzle.

Unfortunately as the pressure increases so does the cost and maintenance so this is not as simple as it seems.

There are several items to keep in mind when looking at the cost per hour to run a waterjet.

This is also why you rarely see production pumps that run more than 60 000 psi 4 100 bar.

The width of the waterjet cutting stream is typically 0 04 inches or 1 mm.

180 south ave po box 517.

To calculate your material cutting speed and waterjet pump pressure download the kmt 60 000psi 90 000psi cutting calculator on your computer.

Hourly cost to run an waterjet the long answer.

Custom materials add edit or remove materials custom orifices nozzles add orifice nozzle combinations currency units change currency measurement system and number formatting.

The more water you flow the faster the cut.

513 874 5550 call us today.

90 000 psi 125 hp pump running two cutting heads.

The jet was not a very rigid precise cutting tool and so early abrasive jets say in the 80s were used if you had absolutely no other possible way to cut the material.

These costs should be relatively universal regardless of the manufacturer of your waterjet.

Parts cut using ordinary waterjet cutting will have a slight taper along the cut edge of the part typically between 0 0005 inches and 0 01 inches.

Precision water jet cutting serving the cincinnati dayton areas and beyond.

Then you would pick an abrasive jet and expect to have a very imprecise cut almost like oxy acetylene burning.